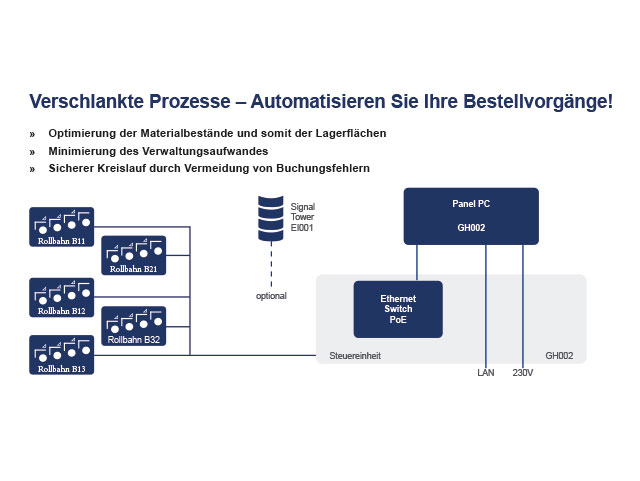

Automatic interlocking & cycle security

Identification of the supplied Kanban boxes at the interlock. Rejection of the material not belonging to the shelf. Automatic registration of material withdrawals. Detection and prevention of incorrect returns.

Separate laser measurement within each roller conveyor.

Use of different container models, pack sizes and shapes within the rack by simply adjusting the parameters.

Touch panel PC

Direct display of rack occupancy, status information and stored goods details on the panel PC.

Data consistency

Recording of all stored goods on the shelf in a database. Automatic recognition of all removed goods after a power failure.

Customized sizes

Fast and easy implementation of the HERMOS solution for retrofits, new builds or extensions, regardless of rack manufacturer and type. Flexible design of rack expansion by changing the parameterization specifications. Fast and uncomplicated configuration of individual rack lanes.

Simple process integration via Ethernet / FIS#ApplicationServer.

Integration of the RFID solution into the customer network via Ethernet and individual connection to the existing ERP system. Updates and parameter changes can be entered via remote maintenance. Further advantages bring the optional use of the FIS#ApplicationServer (HERMOS-own software for the

manufacturer-independent connection of technical systems).