The control and management platform for your automation.

FIS is based on a powerful software framework and is adapted to the respective application in the corresponding automation industry with characteristic modules matching the application purpose. The framework provides the basic functions, including communication, reporting, alarming and archiving, while the application-specific modules integrate the special functions of the respective industries.

As a client-server system based on current operating systems and software technologies, FIS is also equipped for future requirements. In addition to the modular structure and the included driver interfaces, a central data management is just as advantageous as the integrated filter and export functions. Of course, FIS also fulfills the most basic requirements of a modern control system.

The integration of all common industrial and building automation protocols such as OPC, OPC-UA, SNMP, ICMP, MQTT, BACnet, S7, TwinCat ADS and Modbus provides a wide range of possibilities to efficiently integrate the FIS software platform in your area of requirements and thus achieve maximum efficiency and productivity.

In addition to the standards, FIS also offers a wide range of proprietary connectivity options such as connections to beamers, elevators, escalators, access control, camera systems and much more. If required, new couplings can also be implemented.

What applies to the desk in the “tangible” world also applies to the digital world. As the saying goes: Focused work is only possible if the desk is tidy so that only what is currently needed for work is on it, and then only as long as it is needed.

This is exactly the approach we took to heart when designing the new FIS interface.

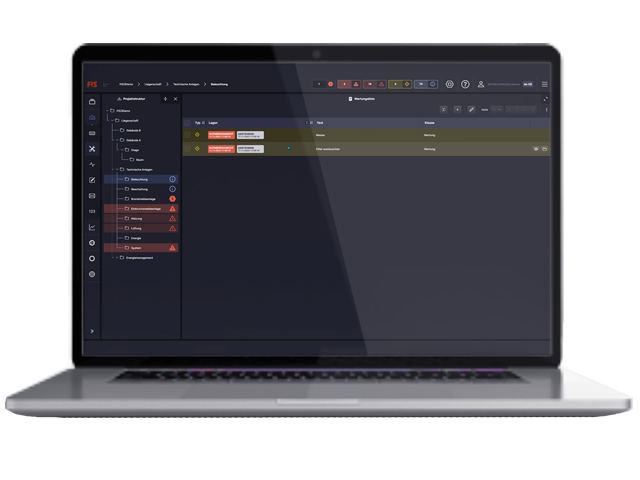

In addition to a sorted and tidy basic structure of the interface, it is also important to make the project-, user-, role- and task-specific functions and elements accessible accordingly or to tidy them up so that the focus can be concentrated on the essentials.

With its user interface, FIS offers only those functions that are necessary for the relevant selection, the logged-in user and his current task (role- or task-based). The visualization adapts accordingly when the selection is changed. It is not necessary to log on, log off or log on again or even to open another application.

The user interface is adapted to all project requirements by pure configuration, from small plant operating panels to higher-level management systems.

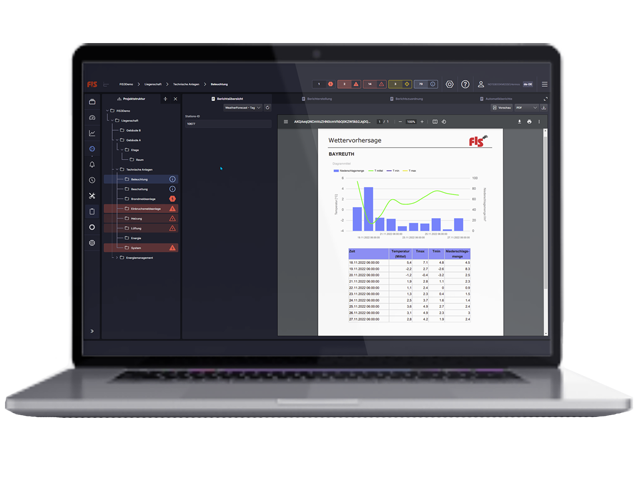

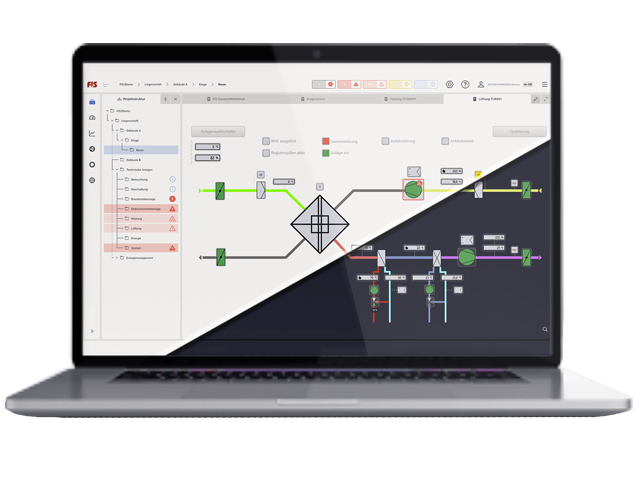

The FIS user interfaces have a dark and a light mode as standard. Depending on the lighting conditions, the target device and personal perception, the contrast or the basic visibility of the important information is increased. Switching depends on the settings of the operating system or the respective browser. Switching can also be specified via the user settings.

(Messages, Alarms & Events)

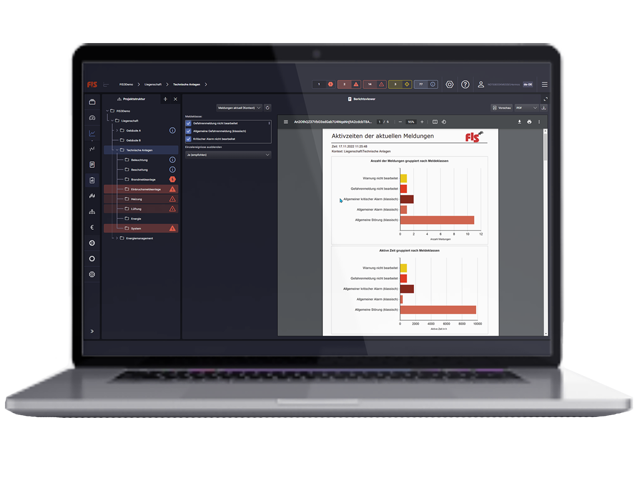

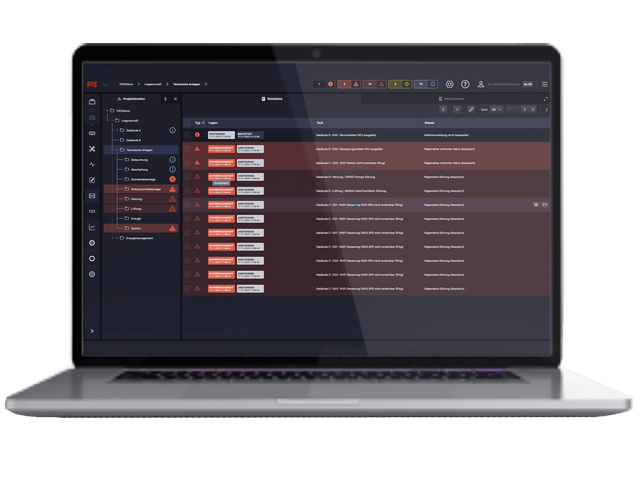

Current messages reflect the plant status in text form. These can be displayed in different message or alarm lists depending on priority and selection. Users can add their own messages to the system or add information to existing messages.

Such simple viewing and processing of messages often does not meet today’s requirements. An integration of the FIS process management into the lived business processes is indispensable. Thus, in addition to its own resubmission of a workflow system, FIS also enables coupling with external systems such as CAFM or ERP systems for data exchange in connection with alarm handling and messages. Messages can also assume customer-specific statuses/locations and generate appropriate attention according to their importance.

FIS offers proven QR technology for automation systems also within FIS. With QR codes, you can navigate to any position in the system. Scanning the stored code with your mobile device automatically opens the user interface and calls up the stored destination there, in this case the plant, the information focal point or the room. In this way, you can quickly and easily access the necessary information. The QR codes with the navigation to the plants can be visualized and printed in a simple way with ready-made reports. Attach the QR codes where you need them. FIS also supports QR codes already provided by the customer.

Released and tested updates can be obtained automatically via the Internet. Local distribution on site without Internet access is also possible.

Certified BAWS and energy data management certified according to ISO 50001, compliant with DIN EN ISO 16484 and AMEV 2011

Connections to a wide variety of systems from all areas of automation are included in the system.

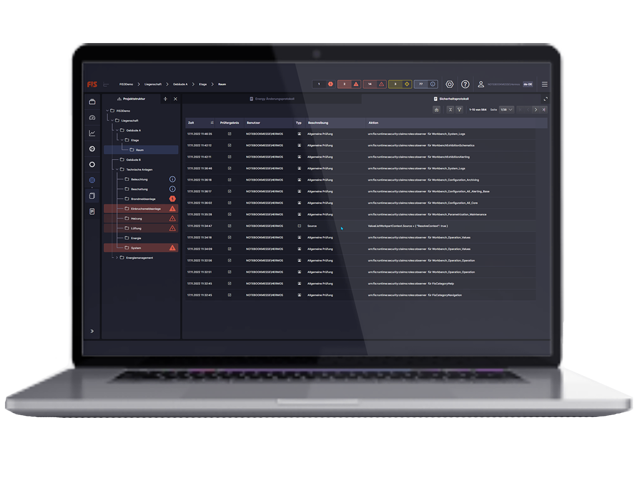

Tools for monitoring your own infrastructure integrated – self-diagnosis, log files in various levels, communication monitoring of network participants and programs, as well as recording access to the system are important components of any control system and therefore also available in FIS.

Communication with other control systems is done with standards.

Data exchange with SAP, PitFM, Navision etc. via XML/Soap, OPC, database, API or customer-specific coupling

Common object or aggregate symbols are included in the system in various forms.

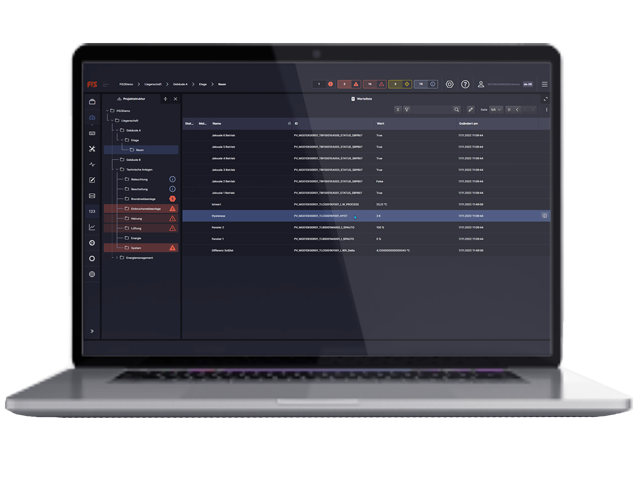

FIS supports asset key-based identification and configuration across the entire control system.

Project creation based on deployment-optimized templates possible.

Structure and function of the user interface can be customized as desired

FIS supports touch and/or mouse and keyboard operation. The user is “guided” through the system.

Filtering and searching by any criteria possible across the entire system

Manual or automatic export of current and aggregated data and reports

Supports local and domain-dependent user accounts and user groups, use of single sign-on possible

Shows access to all secured functions, for example for audits

Imported CAD plans with dynamic data

Process or flow diagrams for visualization of interrelated processes/plants

Intuitive operation of technical systems through vector-based visualization

Drag-and-drop supported graphics creation directly in the web client

Quick overview of relevant information through individual portal pages

Flexible recording options and powerful long-term archiving of data through segmentation of the database

Visualizes value development in curves over several time axes

Diverse evaluation options enable targeted measures for process improvement

Seamless reporting and documentation with standard and custom reports

Reporting enables integration of customer-specific processes and operations in addition to standard functions

Location-independent plant monitoring through alarming with escalation levels and shift schedules, e.g. by e-mail, printer, fax or SMS

Certified energy data management, as a stand-alone module or fully integrated

Event-oriented or interval-controlled maintenance, based on process data and coupling to the strategic management level

Availability evaluations provide an overview of the malfunction behavior of the plants and thus supply data for maintenance or future investment decisions.

Cross-control and cross-protocol time switching possible

Use of online maps for navigation or clear display of dynamic data

Use of context-related system-independent information possible

Here you can find a part of our successfully processed customer projects. Our primary goal is to satisfy our customers with our products and services in the form of customized solutions in the long term. Take advantage of this efficiency, the innovative spirit as well as the know-how of HERMOS.