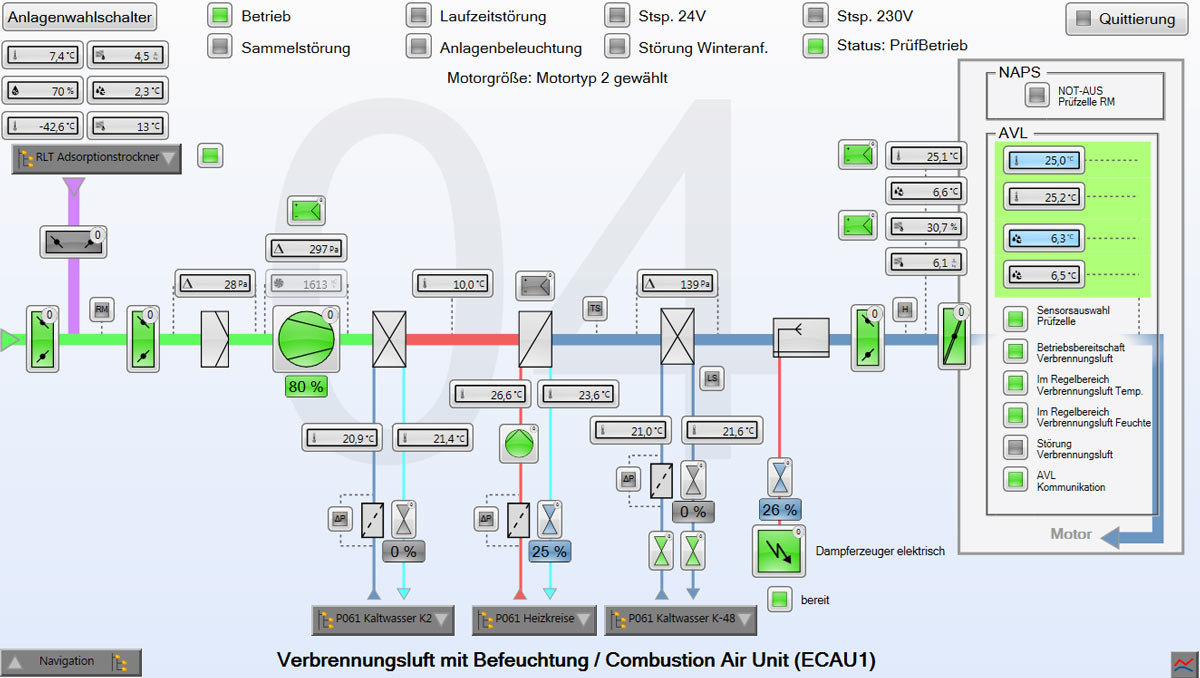

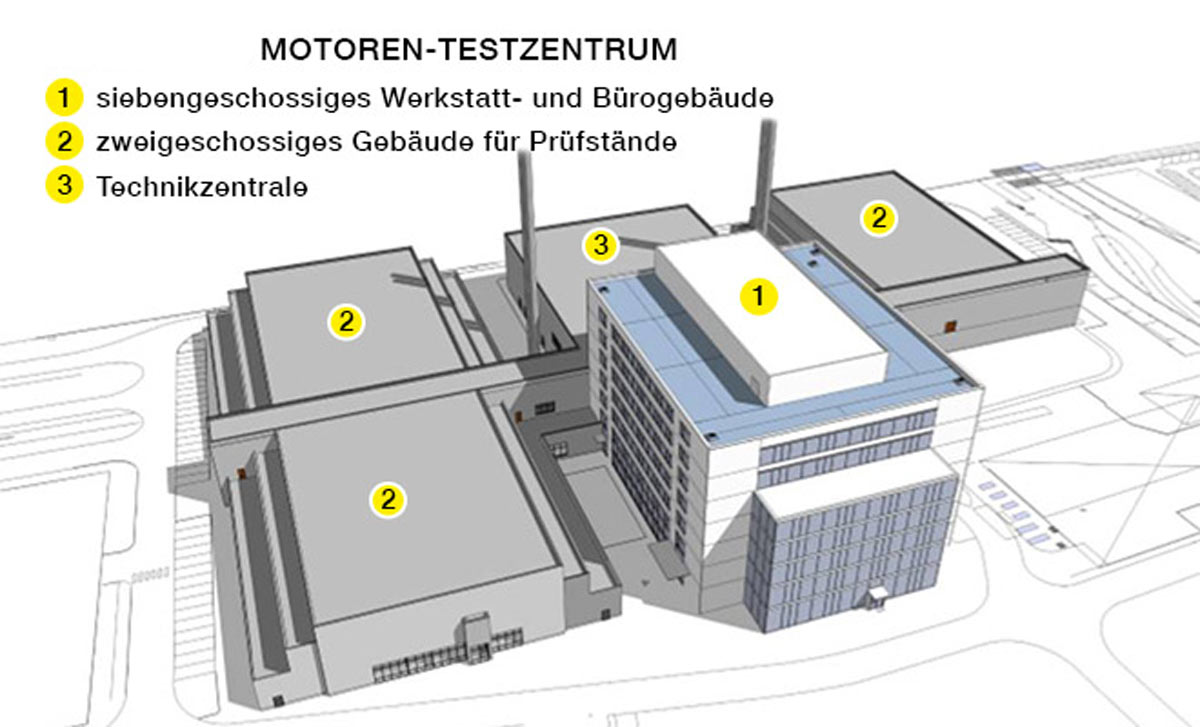

The development and test center of Segula Technologies, a global provider of automotive engine testing services in Rüsselsheim, Germany, includes a seven-story workshop and office building, a two-story building for test benches, and a technical center. Testing is carried out in 48 test benches of the latest generation. In addition to the building automation, HERMOS also realizes the complete automation of all engine test benches including safety control and energy monitoring. HERMOS’ own management and operating unit FIS is used for central monitoring, control and data acquisition of all systems.

Customer benefits

- Economically sustainable operation of the test benches

- High plant availability due to fast response times

- Targeted measures for troubleshooting due to clear, detailed information

- Centralized data acquisition and analysis of test rig operations

- Provision of data to other systems

Technical information

Bus systems: Profibus, Profinet, Modbus TCP, Modbus RTU, M Bus, IEC 60870-5-104

Protokol: BACnet

Manufacturer PLC and Number: Beckhoff (75), Schneider Electric (21), Saia-Burgess Controls (1)

Physical data points: ca. 30.000

Virtual data points: ca. 80.000

Features & Highlights

One of the greatest challenges was to implement the control of the interacting systems at an appropriate speed and quality and to transmit the large amounts of data for all test stands to the central FIS server using BACnet. In order to be able to react appropriately in case of errors, a distributed safety system based on a safety matrix was implemented and visualized. Existing test stands were upgraded electrically, in terms of software and control system technology to hydrogen operation.