Over 1000 systems implemented on production lines!

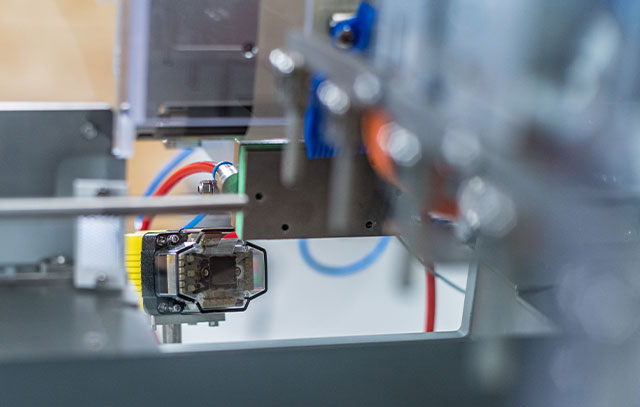

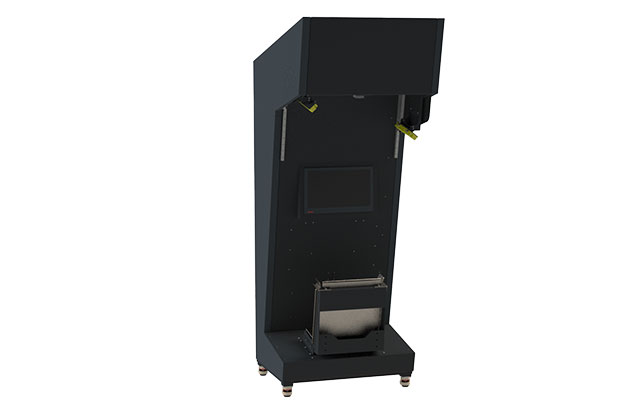

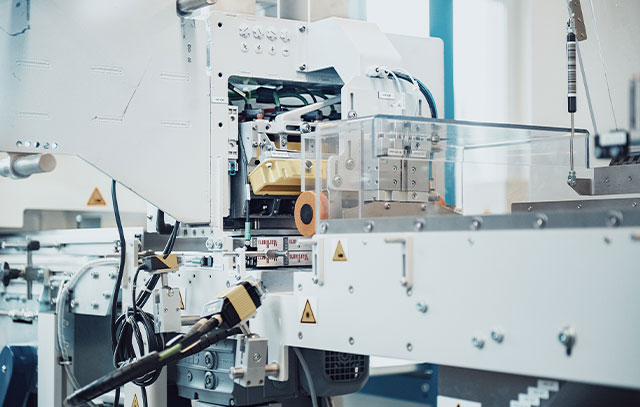

HERMOS Track&Trace applications overcome the lack of physical linkability by marking (printer or RFID) and reading (camera or RFID reader) the manufactured products directly at the production line or within the factory logistics chain. The ERP/MES level or any other target database is supplied with physically aggregated data via our system solution. Through true physical mapping, tracking of production data is elevated from a purely quantitative level to a qualitative level. This enables the basis of product integrity.

Customer benefits

With HERMOS, you can capture and verify product information and its status by tracking a product’s journey from raw material sourcing through manufacturing to each step in the supply chain.

- Seamless traceability of the entire production and logistics chain

- Transparent design of manufacturing processes

- Tracking efficiency of up to 100%

- Digital networking through reading and marking

- Optimization of process steps within planning and production